Topic 12.1.1: Defining and Configuring Phase Logic

- Through the execution of phases, the batch management system controls and monitors batches.

- A phase is an independent processing action that can reside in the server or client platform, a programmable logic controller, or any other control system used to evaluate logic and/or interface with manufacturing equipment.

- Phases can reside in many different locations. The interface between the batch management system and the phase is standard and must follow certain guidelines.

- Phase Block Design Guidelines

- Definition of a Phase Block

- The basic building block used for coordinating the control system communication with the flexible batching system is the phase block.

- Also called a phase, the phase block is a small portion of control system logic that conducts an independent action within a process or transfer class associated with a batch. Some examples of phase blocks are ramp heat, ramp cool, soak, and bulk add.

- Phase blocks are associated with each unit or connection in a particular modeling class.

- The following list provides some of the ultimate goals of phase block logic. While it is likely that processes will exist that prevent satisfying all of these goals simultaneously, achieving the following goals should always be the primary objective.

- Phase logic should be modular for easy duplication and transferability.

- Phase logic must utilize the standard interface between the control system and the supervisory computer.

- Phase blocks can be written independently of one another.

- Phase blocks should be control system independent.

- The control system memory map should not be confining.

- The addition of process equipment should be done easily with little code revision.

- Phase logic structure should be standardized for ease of troubleshooting.

- Phase logic should be available for multiple use within the operational program.

- Phase logic should be available for multiple use within the operational program.

- Phase logic should consist of a minimum amount of code without compromising functionality or safety.

- Phase logic complexity should be geared to the level of the technical support staff.

- Phase Block Rules of Operation

-

- This section summarizes the general rules to be followed when planning and constructing the operation of a phase block and/or complete process program. These rules will be discussed in greater detail throughout the remainder of this document.

- All items, except outputs, specific to a particular phase block should reside within that phase block.

- An interlock is a pre-run condition of a phase block that prevents the phase block from being operated.

- An alarm is generated by either a runtime conditional error or a device failure.

- Critical alarms put the corresponding phase block(s) on hold if they are currently executing.

- On an initial control system power on sequence, the status of all phase blocks should benready or interlocked, and all of the outputs must be in a de-energized state.

- In the event of a batch system to control system communications error, any phase in the run mode should continue until done, and the control system should wait for communications to be restored for the next command.

- The manual operation of output devices must be addressed with regard to the status ofnthe phase logic blocks that utilize the outputs.

- It is the responsibility of the control system logic to recognize and react to unit control bits. These control bits include Unit Hold, Unit Restart, and Unit Abort.

- This section summarizes the general rules to be followed when planning and constructing the operation of a phase block and/or complete process program. These rules will be discussed in greater detail throughout the remainder of this document.

-

- Definition of a Phase Block

- Function Block Diagram

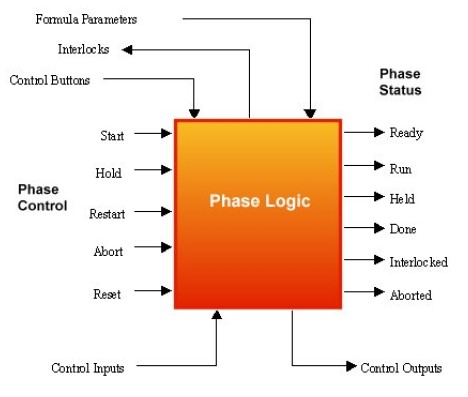

- There are eight main components to a phase block. These include the phase control bits, phase status bits, control inputs, control outputs, formula parameters, control buttons, interlocks, and alarms.

- The items are transmitted between the control system and the batch control system via tags. The phase block acts on this information to control the process equipment. Each of the components will be discussed in greater detail in further sections.

Last modified: Thursday, 7 May 2020, 5:44 PM