Topic 7.1.1: Recipes

- Master Recipes

- The batch control system provides a recipe management system that enables Master Recipes to be constructed and edited. Master Recipes are not process line specific. They can be assigned to any process line that has the classes of process equipment defined in the recipe.

- A Master Recipe is considered a Control Recipe when a Train is assigned to it and the Batch Manager initializes it. A Control Recipe is process line specific.

- A Master Recipe is not size specific, but is scalable to the batch size defined by production scheduling. All formula quantities for ingredients, intermediates, by-products and finished goods are entered as either actual quantities or can be expressed as a percent of the batch.

- Batch Manager scales quantities expressed in percentage when the batch is initialized.

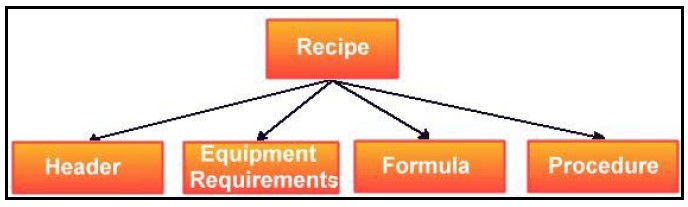

- Contents of a Master Recipe

- There are four parts to a recipe:

- Header

- Equipment Requirements

- Formula

- Procedure

- There are four parts to a recipe:

- Recipe Header

- A Recipe Header documents and identifies the recipe. Identification consists of a Recipe ID, Recipe Name, Recipe State, Recipe Type, Product ID, Product Name, Minimum Batch Size, Maximum Batch Size, Default Batch Size, and a Comment.

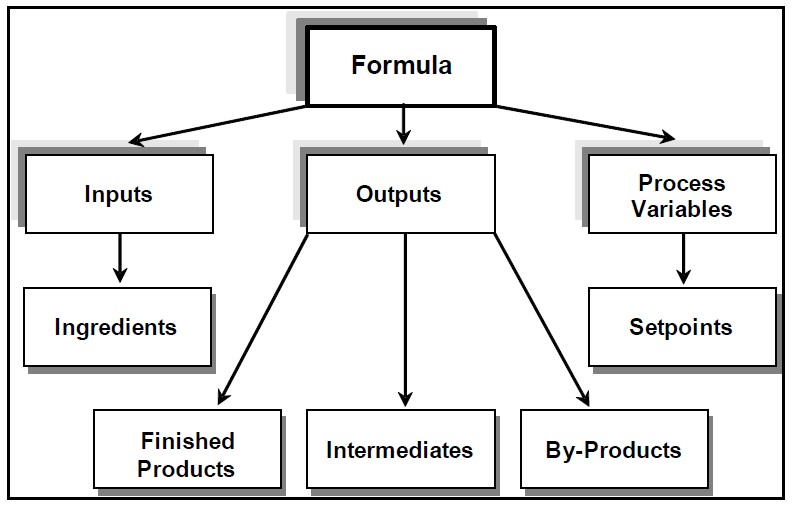

- Formula

- The Formula specifies the inputs (raw materials, ingredients), the outputs (intermediates, finished goods, and by-products), and the process variables for a recipe.

- Process variable values are entered in as actuals. Input and output quantities are entered as actual quantities or in percent. Default Tolerances for ingredients and process variables will be automatically displayed.

- Tolerances can be made recipe specific, if desired, or can be disabled altogether.

- Procedure

- Procedures define the sequence of process actions needed for the Recipe Editor to execute one batch of a recipe. A procedure is constructed by using unit procedures, operations, phases, transition logic, branch and loop objects.

- Unit procedures and operations are associated with a process or transfer class and defined in the recipe. Phases are defined when constructing the Process Model.

- Transition Logic provides the ability to re-direct the execution of a procedure based on the result of a Boolean expression (true or false). Expressions are constructed using process and transfer class tags and operator yes-no questions.

- Branch Objects allow the recipe builder to execute simultaneous operations and phases, execute one of many operations or phases, and execute operations simultaneously on two or more units within the same process class.

- Loop Objects allow the recipe builder to re-execute operations and phases based on an evaluated transition logic expression.

Last modified: Monday, 4 May 2020, 10:03 AM